Boeing parts manufactured at AMP

Further to last week’s great news about McLaren, now Boeing have announced they will invest £20 million in a joint venture high-tech manufacturing facility together with Sheffield University here on The Advanced Manufacturing Park. This is the first time Boeing have invested anywhere in Europe and its a great endorsement of The Advanced Manufacturing Park, The Northern Powerhouse concept and shows confidence in the future of Great Britain’s economy as a whole. They will manufacture advanced flight controls such as aerilons using techniques developed at the AMRC also on the AMP nearby.

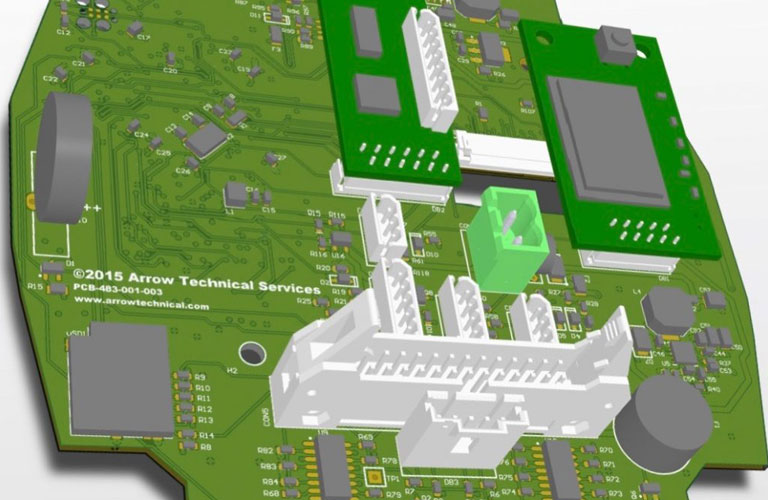

Arrow Technical have long been actively involved in advanced aerospace electronics designs from the very outset. Our very first projects over 20 years ago were done for BAe Systems at Warton and we have done further projects for Rolls-Royce also. Its great to welcome another global aerospace company onto the park which only enhances our reputation further.

Boeing’s new factory on the AMP

Here at Arrow Technical, we are used to the rapidly advancing technology capabilities in aerospace and we exist to advise our clients, be they in aerospace, automotive medical, scientific, industrial or consumer electronics markets.

For more information on how we might help you, visit our website at www.arrowtechnical.com